Twin Wall Flue Insulated System Chimney

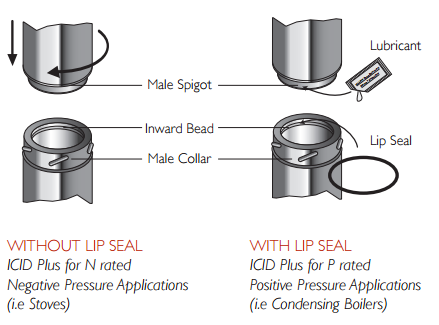

Our Eco ICID range has evolved into a multi-application system adaptable for Dry (D), Fu (W) and even Positive Pressure (P) applications.

At Schiedel, we pride ourselves on our technology and innovation and this heating season introduce our evolutionary 3-in-1 system:

ICID Plus Twin Wall Flue, is ideal not only for traditional stoves but also for pellet stoves, biomass appliances, mini/micro CHP and even condensing boilers capable of withstanding positive pressure.

The system is designed so that the outer case is load bearing and the inner liner is free to expand independently, therefore thermal expansion is accommodated within each and every joint of the system.

- Available in two versions with a choice of either a bright annealed or a matt black painted stainless steel outer case

- ICID Plus is available in the following range of diameters:- 100, 125, 150, 180 and 200mm

Video

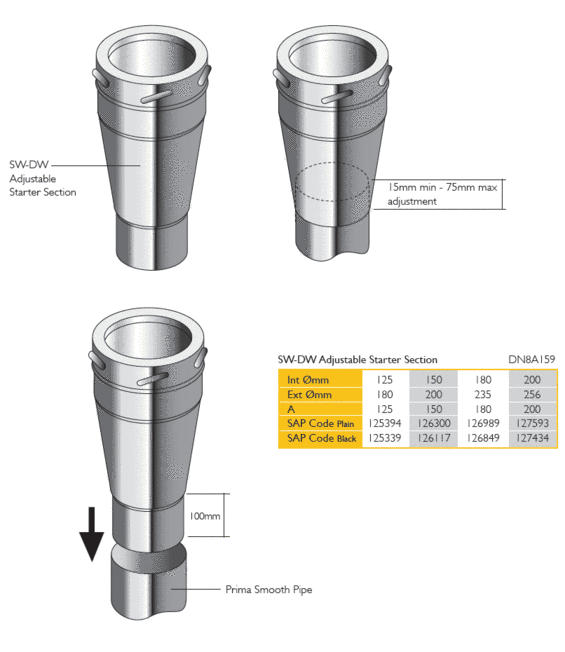

The following video shows how easy it is to install the Double Wall Adjustable Starter Section onto a stove and also how to remove it for servicing and maintenance.

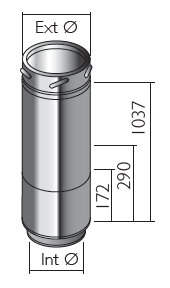

ICID Plus Double Wall Adjustable Starter Section

ICID Plus Double Wall Adjustable Starter Section

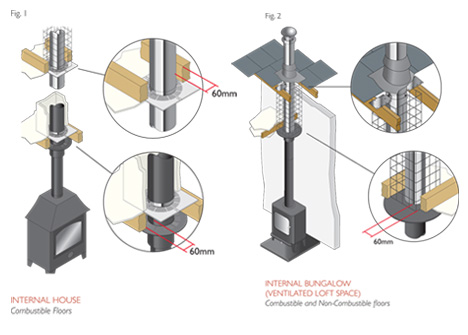

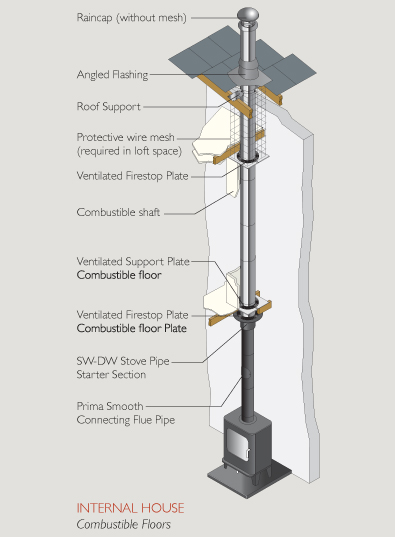

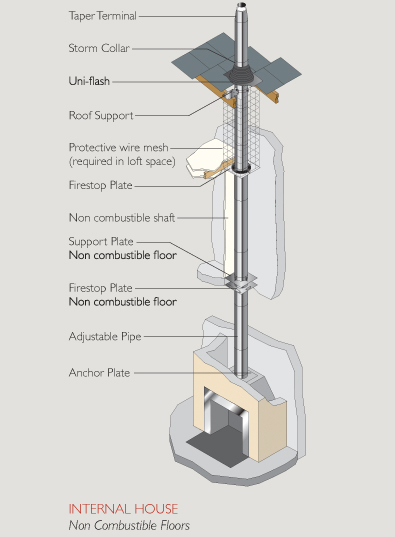

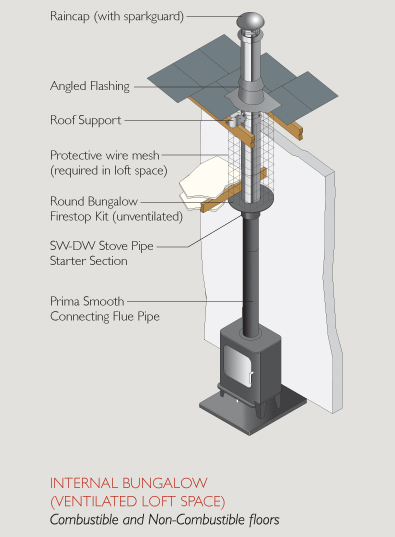

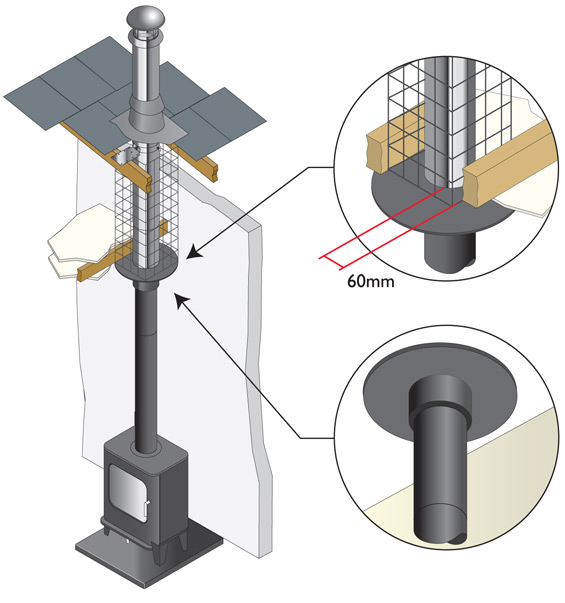

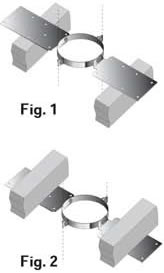

The roof support is supplied as a kit complete with two side plates for fixing to the roof trusses, a band to give lateral support to the chimney as it passes through the roof, and 3 self tapping screws, which are secured to the chimney through the band to give a load bearing capacity. When the plates are installed above the roof trusses as in Fig.1 the maximum number of pipes, which may be suspended from the roof support is 6 x 1m pipes.When the plates are attached below the trusses as in Fig.2 the maximum number of pipes, which may be suspended is 4 x 1m pipes.

The roof support is supplied as a kit complete with two side plates for fixing to the roof trusses, a band to give lateral support to the chimney as it passes through the roof, and 3 self tapping screws, which are secured to the chimney through the band to give a load bearing capacity. When the plates are installed above the roof trusses as in Fig.1 the maximum number of pipes, which may be suspended from the roof support is 6 x 1m pipes.When the plates are attached below the trusses as in Fig.2 the maximum number of pipes, which may be suspended is 4 x 1m pipes.

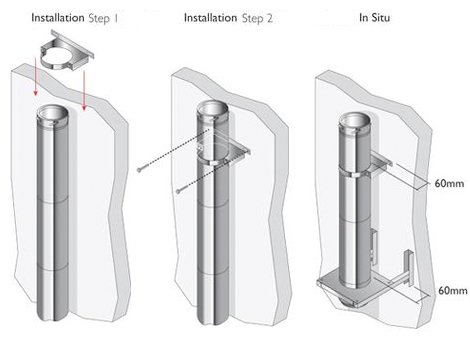

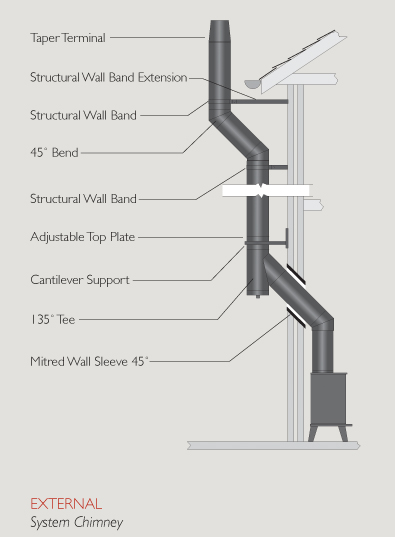

A new retrofit wall band has been added to the range to make life easier for the installer. With this new component available in either bright annealed steel finish or matt black to match the outer case of the chimney, the installer is able to install the chimney faster. The wall band can simply be lowered over the top of the pipe section, and fixed in place without having to remove the pipe section first.

A new retrofit wall band has been added to the range to make life easier for the installer. With this new component available in either bright annealed steel finish or matt black to match the outer case of the chimney, the installer is able to install the chimney faster. The wall band can simply be lowered over the top of the pipe section, and fixed in place without having to remove the pipe section first.